Socket Head Cap Screw

Socket Head Cap Screw Mnaufacturer

Fixicore is one of Socket Head Cap Screw manufacturers in China since 1986. As a leading & professional China-based Socket Screw factory, our company manufacturing Many kinds of Socket Screws, Such as set screw, Socket head cap screw and with different materials; and also customized products, Contact us today to request a free quote or more information.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Socket Head Cap Screw

What is a socket head cap screw?

A socket head cap screw (SHCS) is a type of fastener that has a cylindrical head with a flat top surface and a hexagonal recess for driving. The shank of the screw is threaded, either partially or fully, depending on the application. The defining feature of the socket head cap screw is the internal hexagonal drive, which allows for high torque application using an Allen wrench or hex key.

The cylindrical head of the SHCS has a smaller diameter compared to other screws, allowing it to be used in tight spaces where there is not much clearance. Furthermore, the internal hex drive facilitates higher torque application without the risk of the driver slipping out, which is a common issue with slotted or Phillips head screws.

Socket head cap screws are available in various sizes, materials, and thread pitches. They are often made from alloy steel or stainless steel for high strength and durability.

What are the benefits of socket cap screws?

Socket cap screws, known for their strength and versatility, have become an integral part of various industries. The cylindrical head with an internal hexagonal recess is the defining feature of these screws. Let’s look at the key benefits they bring to the table:

1. High Strength: Made from materials like alloy steel, socket cap screws can withstand high tensile forces, making them ideal for heavy-duty applications.

2. Compact Size: The small cylindrical head is perfect for tight spaces, allowing for effective use in applications where clearance is limited.

3. High Torque Application: The hexagonal recess enables the use of an Allen wrench, permitting high torque application without the driver slipping out.

4. Aesthetic Appeal: With a clean and unobtrusive head, socket cap screws offer a sleek appearance, desirable for finished products.

5. Versatility: Available in various sizes and materials, socket cap screws cater to a wide range of applications, from machinery to electronics.

In conclusion, socket cap screws are an excellent choice for applications requiring strength, precision, and aesthetics, due to their unique design and material properties.

How Does a Socket Head Cap Screw Work?

Socket head cap screws are a mainstay in the world of fasteners, widely favored for their strength, aesthetic appeal, and versatility. But how do these screws function? In this article, we’ll dive into the mechanics and applications of socket head cap screws.

Design and Components:

Socket head cap screws are characterized by their cylindrical head, which is slightly larger than the threaded shaft. The top of the head is flat, and there is a hexagonal recess in the center. They are typically made from high-strength materials like alloy steel or stainless steel.

Installation Process:

To install a socket head cap screw, an Allen wrench or hex key is used. The tool is inserted into the hexagonal recess on the screw head. This design enables the application of high torque, which is crucial for ensuring a secure fastening. The threaded shaft of the screw is then inserted into either a pre-threaded hole or coupled with a nut.

As the screw is turned, the threads engage with the mating threads in the hole or nut, drawing the screw upward. This causes the head of the screw to press against the surface of the material being fastened, creating a clamping force that holds the components together. The absence of slots or crosses on the screw head, as seen in standard screws, minimizes the chances of the driver slipping out, thus reducing the risk of stripping or damaging the screw.

Advantages and Functionality:

High Clamping Force: One of the primary functions of socket head cap screws is to provide a high clamping force. This is particularly important in applications where the screw needs to withstand heavy loads or vibrations.

Precision: The use of an Allen wrench allows for precise control over the tightening process. This is advantageous in applications that require exact positioning and torque.

Space Saving: The compact design of the head makes these screws ideal for applications with limited space. The head’s small diameter allows it to fit into counterbored holes, sitting flush or below the surface of the material.

Aesthetic Appeal: The clean and streamlined appearance of socket head cap screws is aesthetically pleasing, making them a popular choice for applications where the fasteners are visible and a neat finish is desired.

Strength and Durability: Made from high-strength materials, socket head cap screws are durable and able to withstand high levels of stress, making them suitable for heavy-duty applications.

Applications:

Socket head cap screws are versatile and can be found in a variety of applications. In machinery, they are often used for securing parts and components. In automotive applications, they are employed in engine assemblies and other areas where high strength is needed. They are also commonly used in consumer products, such as electronics and furniture, for their aesthetic appeal and compact size.

Conclusion:

Socket head cap screws work by using a hexagonal recess in the screw head to apply high torque for secure fastening. Their design advantages include high clamping force, precision, space-saving, aesthetic appeal, and strength. These attributes make them an invaluable fastener in a broad range of applications from heavy machinery to everyday consumer products.

Are there different grades of socket head cap screws?

When discussing socket head cap screws, it is essential to understand that there is a variety of types, each designed for specific applications and requirements.

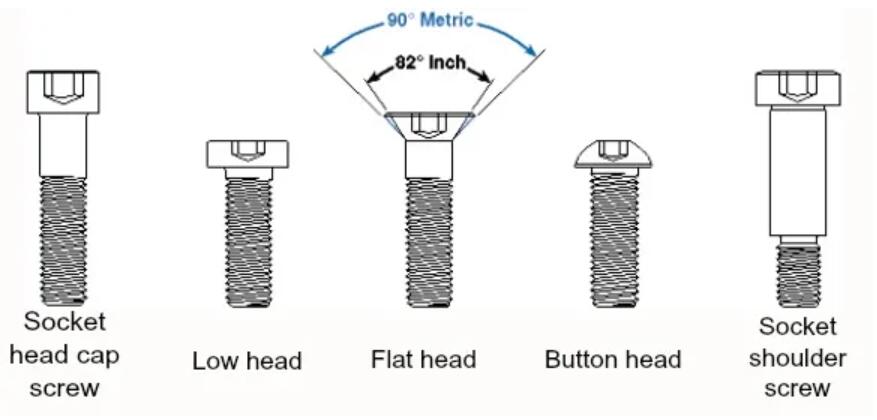

Let’s explore five different types: socket head cap screw, socket low head cap screw, socket flat head cap screw, socket button head cap screw, and socket shoulder screw.

1. Socket Head Cap Screw:

The standard socket head cap screw is probably the most widely recognized. It features a cylindrical head with a flat top surface and a hexagonal recess for driving with an Allen wrench. These screws are known for their strength and are typically made from high-grade alloy steel. They are used in applications where high torque and clamping force are required, especially in confined spaces.

4. Socket Button Head Cap Screw:

Socket button head cap screws have a domed head that is more rounded than the standard socket head cap screws. The head still features a hexagonal recess for driving. The primary advantage of the button head is its aesthetic appeal; the rounded head provides a cleaner and more polished look. It is often used in applications where both aesthetics and strength are important, like furniture, vehicles, or consumer products.

2. Socket Low Head Cap Screw:

Socket low head cap screws have a similar design to the standard socket head cap screws but with a lower profile. This means that the head of the screw is not as tall, making it ideal for applications where there is limited clearance above the screw. Despite the reduced head height, these screws still offer sufficient strength and are commonly used in tight spaces where traditional socket head cap screws would not fit.

5. Socket Shoulder Screw:

Socket shoulder screws are somewhat different from the other types in this list. They have a cylindrical head with a hexagonal recess, but the shank of the screw has an unthreaded shoulder portion that is larger in diameter than the threaded part. This design is used for applications that require rotational or sliding movements, such as in pulleys, gears, and other machinery. The shoulder provides a precise spacing and acts as a bearing surface.

3. Socket Flat Head Cap Screw:

Socket flat head cap screws have a countersunk head, which means the head is conical and designed to be flush with the surface of the material once installed. The head also features a hexagonal recess for driving. These screws are commonly used in applications where it is necessary for the screw head to be flush with or below the surface, such as in machinery, cabinetry, or decorative applications.

Conclusion:

Socket head cap screws come in various types, each tailored for specific applications and settings. Whether it is the standard socket head cap screw for high strength, the low head version for confined spaces, the flat head for a flush finish, the button head for aesthetics, or the shoulder screw for machinery, understanding the differences helps in making an informed choice that meets the requirements of your project. These diverse grades of socket head cap screws cater to a wide range of functional and aesthetic needs.

REQUEST A QUOTE FOR MORE DETAILS

What grade is a standard socket cap screw?

Socket cap screws, widely renowned for their strength and versatility, come in various grades. The grade of a socket cap screw signifies the strength and material properties of the screw. For standard socket cap screws made from alloy steel, the most common grade in the United States is Grade 12.9.

Understanding the Grade of a Standard Socket Cap Screw

Grade 12.9 socket cap screws are made from medium carbon alloy steel and are quenched and tempered. They are characterized by six radial lines on the head, although this marking is not always present on socket cap screws due to the hex recess. The key attributes of Grade 12.9 socket cap screws include high tensile strength, yield strength, and hardness. They are capable of handling a significant amount of stress and are, therefore, ideal for applications where durability and resistance to wear are paramount.

In addition to Grade 12.9, there are other grades available such as Grade 8.8, 10.9, and various stainless steel grades like 18-8 and 316, which are used for different applications based on the requirements. However, Grade 8 remains the go-to grade for standard socket cap screws when high strength is essential.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 577 5768 9696

- Info@fixicore.com